+ BRINE SDS

+ CALCIUM CHLORIDE WITH BOOST SDS

+ BOOST SB SDS

+ LIQUIDOW SDS

+ MELTDOWN SDS

Concrete Slows Down Below 70 Degrees, Don’t Let Your Project

When temperatures fall below 70 degrees, concrete setting slows down, leaving you with longer project times.

WHAT YOU’RE UP AGAINST

Concrete is a staple building material. There’s no way around it. Depending on the temperature, it can take days to dry. Before projects can move forward, concrete has to dry firm and solid.

WHEN CONCRETE IS SLOW, PROJECTS SUFFER

The lower the temperature drops, the longer concrete takes to set. Slow set times create weaker concrete and higher water requirements. Not to mention more work hours on the project.

What Your Up Against

Concrete is a staple building material. There’s no way around it. Depending on the temperature, it can take days to dry. Before projects can move forward, concrete needs to dry firm and solid.

When Concrete is Slow, Projects Suffer

The lower the temperature drops, the longer concrete takes to set. Slow set times create weaker concrete and higher water requirements. Not to mention more work hours on the project.

What Your Up Against

Concrete is a staple building material. There’s no way around it. Depending on the temperature, it can take days to dry. Before projects can move forward, concrete needs to dry firm and solid.

When Concrete is Slow, Projects Suffer

The lower the temperature drops, the longer concrete takes to set. Slow set times create weaker concrete and higher water requirements. Not to mention more work hours on the project.

What You’re Really Spending

Waiting for slow concrete setting costs you time and money.

Millions of tons are used every year, waiting for concrete to set in cold or harsh conditions makes an impact on work hours and overall efficiency.

We all know working in the midwest rarely means ideal conditions. In the best temperatures, concrete takes 48 hours to set. As weather decreases, this time increases.

According to Portland Cement Association, concrete product manufacturing employs 500 thousand people in the United States. This contributes approximately $100 billion to our economy.

In Indiana alone, the concrete industry employs 4198 employees . Minimizing the time on projects can make a huge impact on project timelines and worker efficiency.

Data according to Portland Cement Manufacturers, 2017

How You Can Accelerate

You don’t have to wait for concrete to set in cold weather. You can speed up set time, get more out of work hours and increase efficiency in your projects.

A 2% admixture of calcium chloride at 50 degrees will improve setting times to those attainable at 70 degrees without calcium chloride. The effect is most significant in the 30-50 degree range.

(American Concrete Institute)

Concrete set times are reduced by 65% when calcium chloride is used. Calcium chloride admixture percentages depend on the temperature outside.

(Occidental Chemical Corporation, 2006)

Calcium chloride has been the preferred solution for concrete acceleration for 50 years. With a long history of success, calcium chloride is dependable for all projects.

(Occidental Chemical Corporation)

Using Accelerators

There are options when deciding on an admixture for concrete projects, but some outperform others. Adding accelerators is easy to do and benefits all projects in the long-run.

1. Strategize

Before you start a project, consider when and where your project will take place. Any temperature under 70 degrees will increase time spent on the job. Consider your options before the project starts.

2. Choose Your Admixture

When deciding on your admixture, keep in mind all benefits. Accelerators benefit the entire project when used correctly. Calcium chloride is the preferred accelerator because of its variety of benefits.

3. Calcium Chloride

As the concrete sets, the accelerant increases the hydration and thereby reduces it’s set time by as much as two-thirds. Calcium chloride used as an admixture reduces bleeding and improves workability.

4. Profit and Performance

Enjoy the significant economic benefits in reduced costs, improved overall performance and increased profits. Go into your next project knowing the benefits of reliable concrete performance.

CONCRETE ACCELERATION RESOURCES

Not sure how Calcium chloride can help your next concrete project? Here are some questions we often hear from our clients and reliable resources for all of your acceleration needs.

WHEN SHOULD I USE IT?

Anytime the temperature drops below 70 degrees, setting slows down. The effect is most significant in the 30 to 50-degree range; the rapid setting offered by the addition of calcium chloride to ready-mixed concrete allows concrete contractors to continue to work effectively into the fall and winter months.

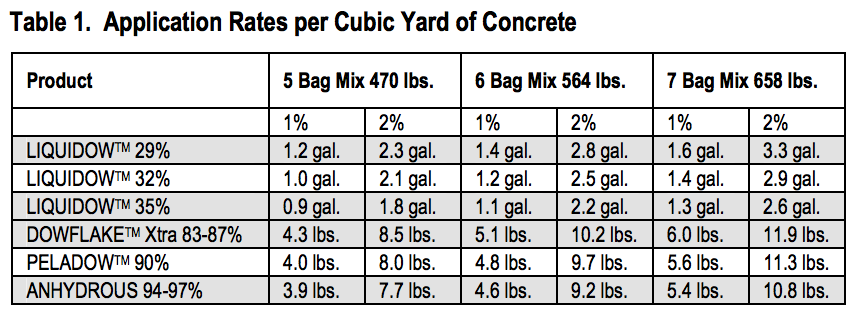

HOW MUCH WILL I NEED?

A 2% admixture of calcium chloride at 50 degrees will improve setting times to those attainable at 70 degrees without calcium chloride. Use the table below for application rates per cubic yards of concrete.

WHY USE CALCIUM CHLORIDE?

Calcium chloride has been used in manufacturing ready-mix concrete for more than 50 years. The primary benefit of calcium chloride in concrete is an accelerated rate of hydration for concrete.

Travis Bartholomew

– Kalamazoo Road Commission General Superintendent

‘We saw a 12,000 ton reduction in salt usage in three years. Adding Calcium chloride reduced winter maintenance costs by more than $360,000.’

WANT TO SPEED UP SET TIMES?

Oops! We could not locate your form.